Call Us : +919825116952

Product Gallery

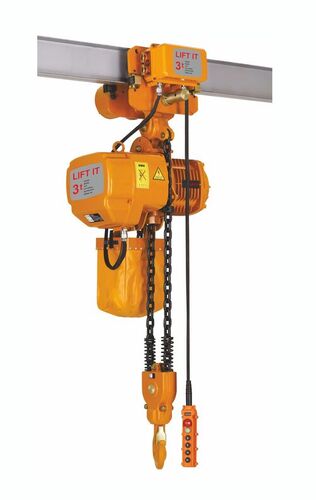

The LIFTIT Chain Pulley Blocks are demanded for lifting the appliances and devices in a safe and speedy way. These allow for simple movement and can lessen the time taken in the process of transportation.

LIFTIT Ratchet Lever Hoists are suited for the tasks of lifting, tensioning and pulling of load to different ton capacities. These can arrange a better working surround where transportation of items is easily accessible.

Magnetic Lifters are effective in safe and speedy transportation of heavy materials. These can hold heavy materials in a firm as well as secured way. These proffer advantages related to labor as well as quality.

The Pallet Trucks are the highly useful material handling solutions, which can lighten the load and contribute in an easier movement of commodities, from one place to another. These time and labor saving trucks can boost the productivity.

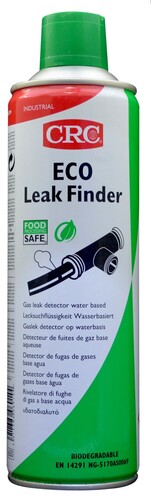

The CRC Aerosol Sprays are made to protect the metals from oxidization produced by salt air, moisture, humidity and other corrosive conditions. With their use, these can evade the need for several disassembly operations.

The CRC Cleaning Sprays of high shelf life have no chlorinated solvents. These can effectively remove the grease, brake fluid, oil and several other hardened deposits. These have quick drying properties at room temperature.

Loctite Adhesives are the patented additives, the adhesive properties of which are highly stronger than regular glues. These are suited for bonding metal as well as other porous & non-porous surfaces.

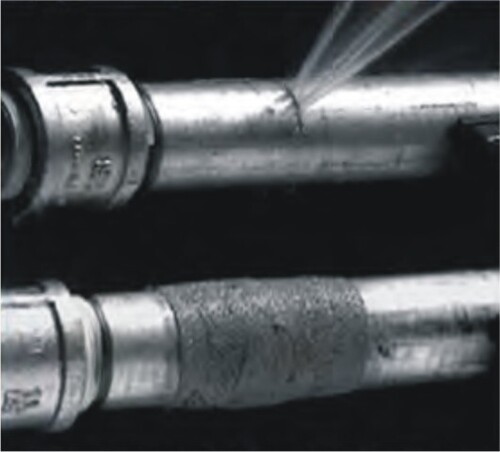

Aquafix Pipe Repair Kits are the versatile as well as easy-to-use leak repair systems, which are used to prevent the leakage in just 15-30 minutes. These can withstand high pressures as well as temperature.

WD-40 is an optimum and best quality rust remover that breaks down the bond between the metal and corrosion. After soak the particular area, these can be applied for few minutes. Prevention as well as removal of rust is ensured.

LED Head Lamps need less power to work and ask for little maintenance. These are needed to enhance the road safety as well as styling of the vehicles.

Anti-Corrosion Tapes are made for the ultimate protection of underground structures, steel structures, immerged structures, overhead structures etc. These are also suited for water & oil pipes, embankments and others.

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |