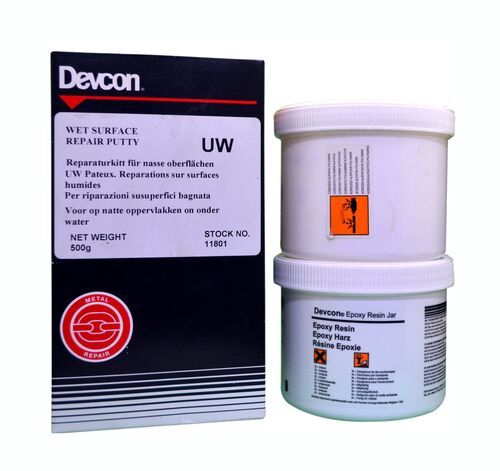

Devcon Aluminum Filled Epoxy Putty

Product Details:

- Material Aluminium Foil

- Application For Sealing, Protecting and Repairing Surface

- Color Grey

- Physical State Liquid

- Click to View more

Devcon Aluminum Filled Epoxy Putty Price And Quantity

- 7999 INR/Piece

- 1 Piece

- 3000.00 - 15000.00 INR/Piece

Devcon Aluminum Filled Epoxy Putty Product Specifications

- Aluminium Foil

- For Sealing, Protecting and Repairing Surface

- Liquid

- Grey

Devcon Aluminum Filled Epoxy Putty Trade Information

- 10 Piece Per Day

- 1-2 Days

- All India

Product Description

Devcon Aluminum Putty F

Product features: Devcon Aluminum Putty Can be machined, drilled, or tapped using conventional metalworking tools Bonds to aluminium, concrete, and many other metals Fill voids or pores in castings.

Limitations: Devcon Aluminum Putty is Not recommended for long-term exposure to concentrated acids and organic solvents.

Specification

| Adhesive Tensile Shear | 2,600 psi |

| Compressive Strength | 8,420 psi |

| Cured Hardness | 85D |

| Cured Shrinkage | 0008 in./in |

| Dielectric Constant | 21.4 |

| Dielectric Strength | 100 volts/mil |

| Flexural Strength | 6,760 psi |

| Modulus Elasticity | 8.0 psi x 10(5) in |

| Specific Gravity | 1.58 gm/cc |

| Surface of Application | metal or aluminum |

| Color | grey |

| Brand | Devcon Aluminum Putty F |

| State/Form | Liquid |

TESTS CONDUCTED :

- Compressive Strength ASTM D 695

- Cured Hardness Shore D ASTM D 2240

- Dielectric Constant ASTM D 150

- Modulus of Elasticity ASTM D 638

- Cure Shrinkage ASTM D 2566

- Adhesive Tensile Shear ASTM D 1002

- Dielectric Strength, volts/mil ASTM D 149

- Coef.of Thermal Expansion ASTM D 696

- Flexural Strength ASTM D 790

- Thermal Conductivity ASTM C 177

Other Products in 'Devcon Epoxy Putties' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |