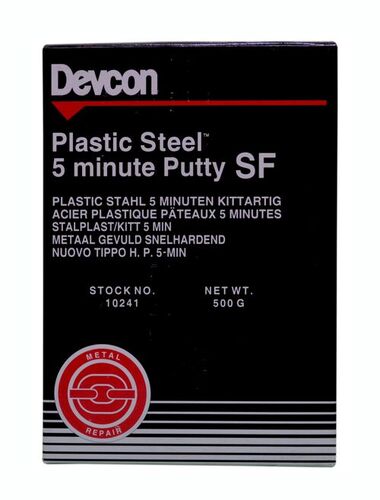

Devcon Plastic Steel 5 Minute Putty (SF)

8100 INR/Piece

Product Details:

- Storage Temperature 22 Celsius (oC)

- Grade Chemical Grade

- Purity 98%

- Application For Sealing, Protecting and Repairing Surface

- Color Grey

- Physical State Liquid

- Click to View more

X

Devcon Plastic Steel 5 Minute Putty (SF) Price And Quantity

- 1 Piece

- 8100 INR/Piece

Devcon Plastic Steel 5 Minute Putty (SF) Product Specifications

- Grey

- 98%

- Chemical Grade

- For Sealing, Protecting and Repairing Surface

- 22 Celsius (oC)

- Liquid

Devcon Plastic Steel 5 Minute Putty (SF) Trade Information

- Surat

- 10 Piece Per Day

- 1 Days

- If order is confirmed we will reimburse the sample cost

- All India

Product Description

DEVCON Plastic Steel 5 Minute Putty SF

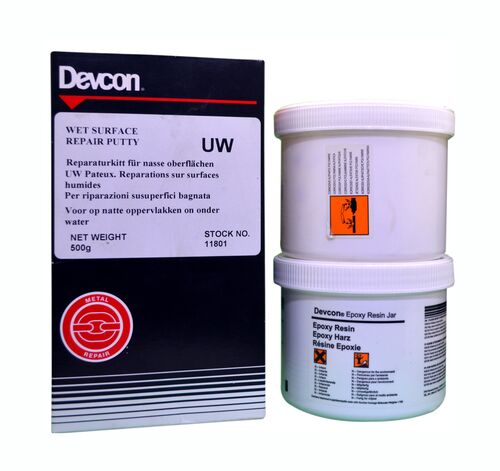

Devcon Online Transformer Oil Leak Sealant

Seals leaking transformers, Oil Barrels, etc.

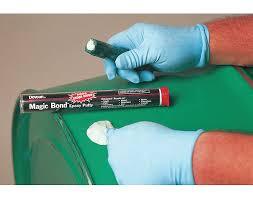

A steel-filled, fast-setting epoxy putty for filling, rebuilding, and bonding metal surfaces.

Restores worn or fatigued metals; patches castings; makes jigs and fixtures; rebuilds pump and valve bodies; restores bearing journals and races

Bonds to aluminium, concrete, and many other metals Resistant to chemicals and most acids, bases, solvents, and alkalis Applies easily to vertical surfaces Machinable to metallic finish

Enter Buying Requirement Details

Other Products in 'Devcon Epoxy Putties' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |