Call Us : +919825116952

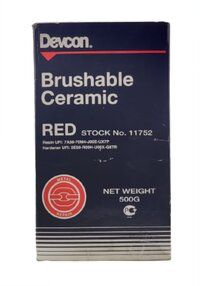

Devcon Brushable Ceramic Red

13500 INR/Piece

Product Details:

- Storage Temperature 350 Fahrenheit (oF)

- Purity 97%

- Application For Sealing, Protecting and Repairing Surface

- Color Red or Blue

- Physical State Liquid

- Click to View more

X

Devcon Brushable Ceramic Red Price And Quantity

- 1 Piece

- 13500 INR/Piece

Devcon Brushable Ceramic Red Product Specifications

- 350 Fahrenheit (oF)

- 97%

- Liquid

- Red or Blue

- For Sealing, Protecting and Repairing Surface

Devcon Brushable Ceramic Red Trade Information

- Surat

- 10 Piece Per Day

- 1 Days

- Yes

- If order is confirmed we will reimburse the sample cost

- All India

Product Description

Devcon Brushable Ceramic Red Coating Food Grade

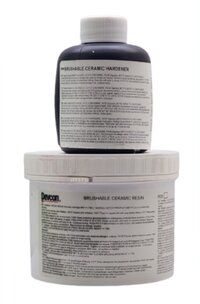

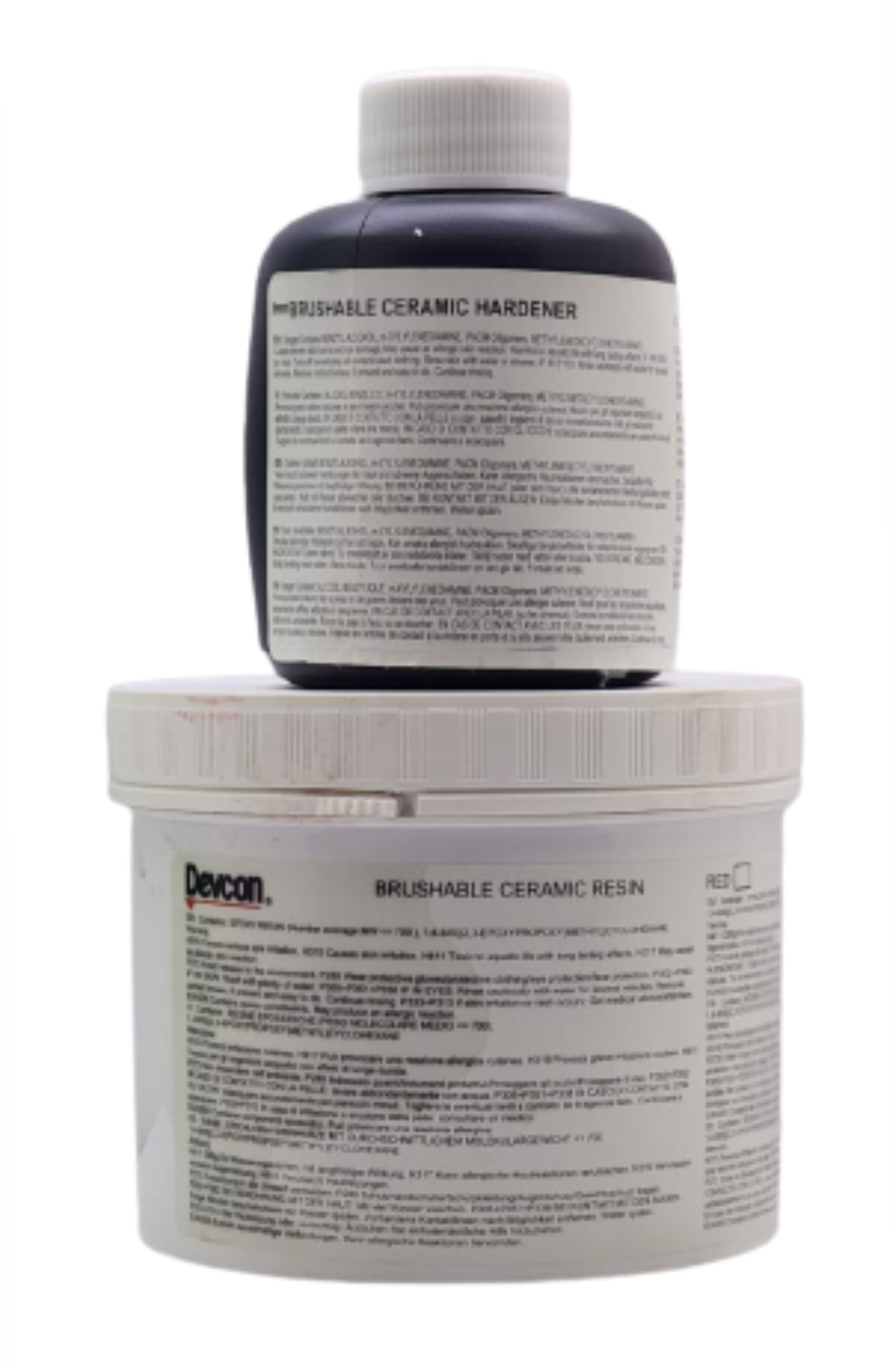

Description: A brush able, high performance ceramic-filled epoxy for sealing, protecting and repairing surfaces subject to erosion, corrosion and wear.

Low-viscosity, alumina-filled, brush able epoxy compound, when applied to a 15-20 mil coating, provides a smooth protective barrier against wear, abrasion, corrosion, erosion, and chemical attack.

Enter Buying Requirement Details

Other Products in 'Devcon Epoxy Putties' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |