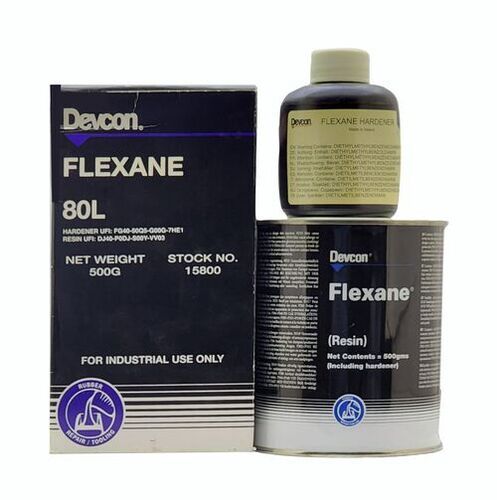

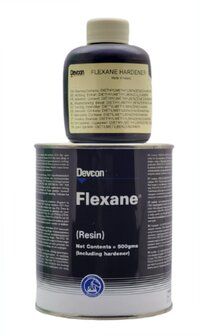

Devcon Flexane 80 Rubber Putty

Product Details:

- Application For Sealing and Fixing Purpose

- Color Black

- Physical State Liquid

- Click to View more

Devcon Flexane 80 Rubber Putty Price And Quantity

- 13500 INR/Piece

- 1 Piece

Devcon Flexane 80 Rubber Putty Product Specifications

- Liquid

- For Sealing and Fixing Purpose

- Black

Devcon Flexane 80 Rubber Putty Trade Information

- Surat

- 10 Piece Per Day

- 1 Days

- If order is confirmed we will reimburse the sample cost

- All India

Product Description

Devcon Flexane 80 Rubber Putty

Description: Devcon Flexane 80 is a Trowel able urethane for repairing and lining process equipment exposed to wear, impact, abrasion, vibration, and expansion / contraction.

Intended Use: Devcon Flexane 80 is a Repair and rebuild conveyor belts Line process equipment to dampen noise, Line concrete control joints. Cast flexible molds, fixtures, and parts Pot and encapsulate .Product features: Trowels on smoothly Cures to tough, medium-hard rubber (Shore 87A)

Flexane 80 Putty Chemical Resistance : Chemical resistance is calculated with a 7 day, room temp. cure (30 days immersion) @ 75 Degrees F)

1,1,1-Trichloroethane - Poor

Aluminium Sulphate 10% - Very good

Cutting Oil - Fair

Gasoline (Unleaded) - Poor

Hypo chloric 10% - Very good

Hydro chloric 36% - Very good

Isopropanol - Poor

Methyl Ethyl Ketone - Poor

Phosphoric 10% - Very good

Potassium Hydroxide 40% - Very good

Sodium Hydroxide 50% - Very good

Sodium Hypo chlorite - Very good

Xylene - poor

Other Details :

TESTS CONDUCTED on Devcon Flexane 80 Putty

Tensile Strength (Urethanes) ASTM D 412

Dielectric Strength, volts/mil ASTM D 149

Cured Hardness Shore D ASTM D 2240

Cure Shrinkage ASTM D 2566

Tear Resistance ASTM D 624

Maximum Elongation ASTM D 412

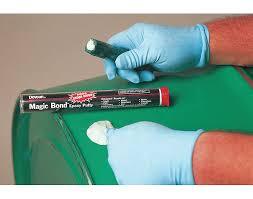

Surface Preparation for Application of Devcon Flexane 80 Putty :

For METAL SURFACES, thoroughly clean area to be repaired, rebuilt, or lined with Devcon Cleaner Blend 300. Remove any oil, grease, or dirt. Roughen surface by grinding with a coarse wheel or an abrasive disc pad. To prime this surface, apply a coat of Devcon FL-10 Primer and allow to dry tack-free for 15 minutes. If the metal surface requires maximum tear resistance or is exposed to moisture, or if submerged in water, use Devcon FL-10 and Devcon FL-20 Primer.

For RUBBER SURFACES, thoroughly clean area with an abrasive pad and Devcon Cleaner Blend 300. Surface can also be roughened with a grinding wheel so that it is coarse and free from oil and dirt that may clog the "pores" of the rubber. Wipe or roughen surface with Cleaner Blend 300 until the cloth no longer picks up the colour of the rubber. The rubber should appear new or deeper in color. To prime this surface, apply a coat of Devcon FL-20 Primer and allow to dry tack free for 15-20 minutes. Use Devcon FL-40 Primer on "hard-to-bond" rubber surfaces as this gives ultimate peeler asistance. Multiple coats may be necessary for porous rubber surfaces. For MAXIMUM ADHESION, sandblast the surface with an angular abrasive until a minimum depth profile of 2-3 mils is met. Blast to near-white finish specification SSPC-SP5 (Steel Structure Painting Council). Prime surface immediately after sandblasting to prevent oxidation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Devcon Epoxy Putties' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |