Call Us : +919825116952

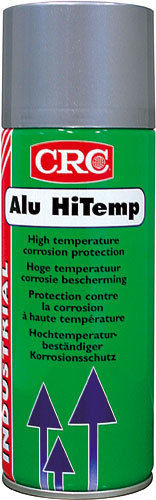

CRC ALU H.T. HIGH TEMPERATURE ALUMINIUM COATING

1050 INR/Piece

Product Details:

X

CRC ALU H.T. HIGH TEMPERATURE ALUMINIUM COATING Price And Quantity

- 1050 INR/Piece

- 1 Piece

- 1050.00 - 1050.00 INR/Piece

CRC ALU H.T. HIGH TEMPERATURE ALUMINIUM COATING Trade Information

- 5000 Piece Per Week

- 5-7 Days

Product Description

CRC ALU H.T. HIGH TEMPERATURE ALUMINIUM COATING

GENERAL DESCRIPTION

High temperature aluminium coating.

A high temperature paint based on silicone resins and active aluminium pigments.Alu H.T. is designed to build a hard lasting finish that will not burn off, chip or peel at high temperatures.

FEATURES

- High thermal stability: resists temperatures up to 600°C.

- Excellent coverage.

- High durability.

- Quick drying at room temperature.

- Very good resistance to temperature fluctuations.

- Good weather stability. Although some loss of gloss can be noticed after extended exposure.

- Totally lead and chromate free.

- No chlorinated and no aromatic solvents.

- Aerosols use dimethylether (DME) propellant for controlled application and film properties.

- Stove pipes

- Stoves

- Heaters

- Kilns

- Incinerators

- Chimneys

- Exhaust manifolds

- Headers

- Engines

- Ovens

- Steam pipes

- Shake aerosol can very well for at least one minute after agitator ball is free. Stir or mix bulk product well to obtain a homogeneous dispersion. Repeat frequently while using.

- Apply to a clean, degreased, dry surface for best results. Remove rust and scale with a wire brush.

- Apply in light, even coats; best results are obtained with 2 lighter rather than 1 heavy coat. Additional coats can be applied after 15-30 minutes.

- Complete curing occurs during use, typically after 1 h @ 200°C or 45 min. @ 250°C.

- When spraying is finished, clean aerosol valve by turning can upside down and pressing button until only propellant escapes. If clogging occurs, remove button and clean orifice with fine wire.

- Do not use on energised equipment. Use in well ventilated area.

- A safety data sheet (MSDS) according EU directive 93/112 is available for all CRC products.

- Appearance : mat aluminium finish

- Resin type : silicone

- Pigment type : non-leafing aluminium

- Specific gravity (@ 20°C)

- aerosol : 0,99

- bulk : 1,11

- Flash point (solvents)

- aerosol : -4°C

- bulk : 42°C

- Coverage (30 mm, dry)

- aerosol : approx. 2,7 m2/can (400 ml)

- bulk : TBD

- Drying times

- To touch : 15 min @ 20°C (45% RH)

- To : 24 h @ 20°C (45% RH)

- To complete cure : 1 h @ 200°C

- Recommended film thickness : 25-30 µm

- Thinner / cleaner : M.E.K., acetates

- Dry film properties (on degreased metal)

- Heat resistance (ASTM D-2485-68)

- Method 1 (24 h cont.) : 600°C

- Method 2 (cycling) : 635°C

- Adhesion on steel (NFT 30038) : 0/1

- Flexibility : pass (after heating to 600°C, 6 mm mandrel, visual)

- aerosol : 12 x 400 ml

- bulk : 750 ml

Enter Buying Requirement Details

Other Products in 'CRC Cleaning Spray' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |