Call Us : 08045802308

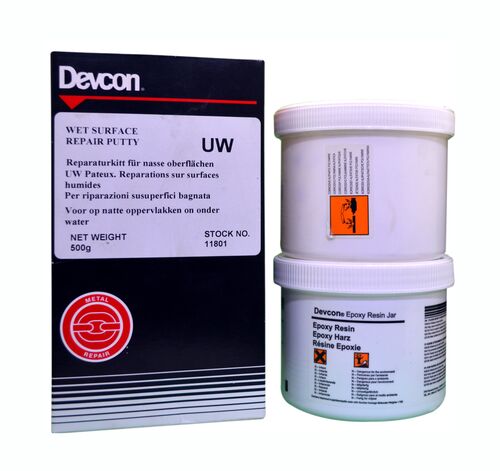

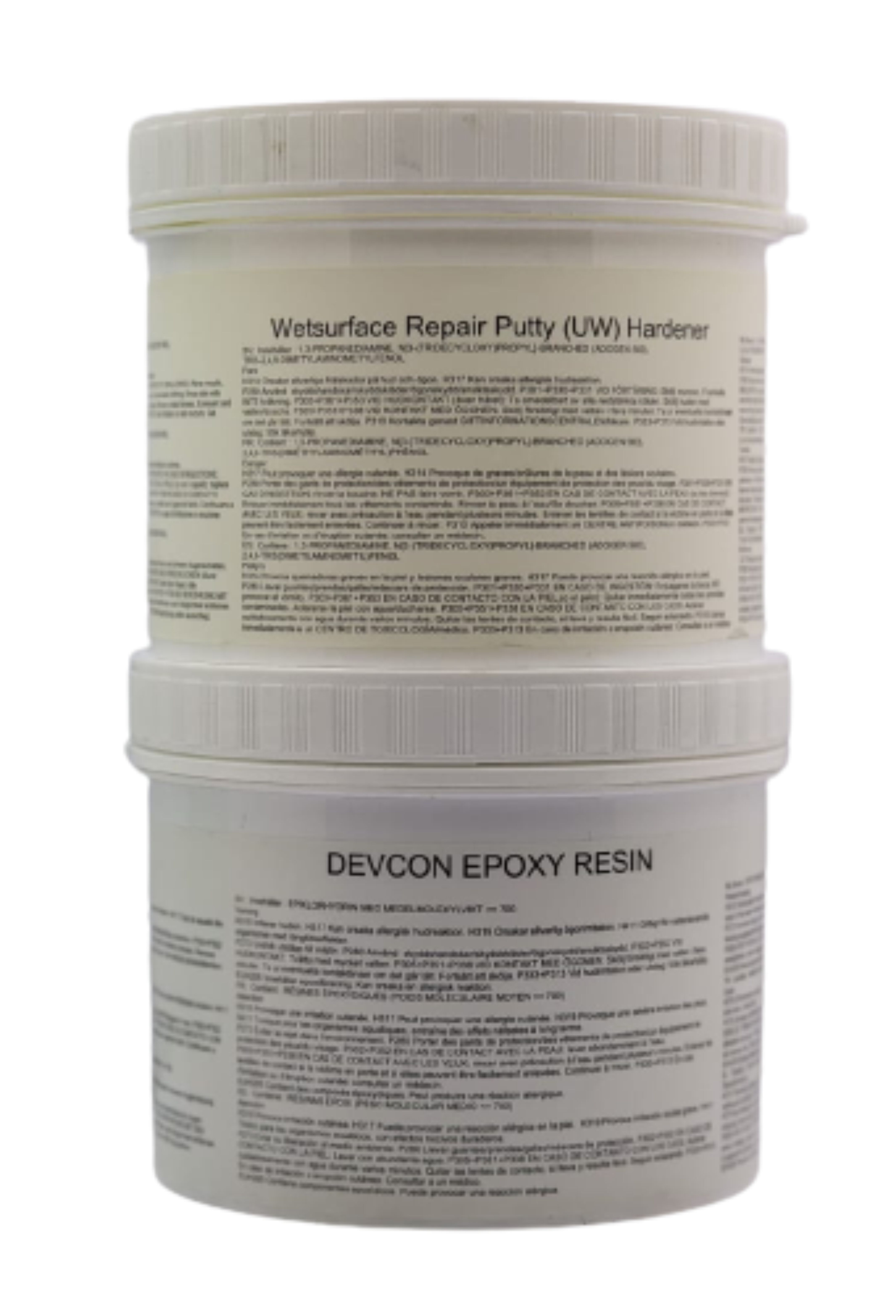

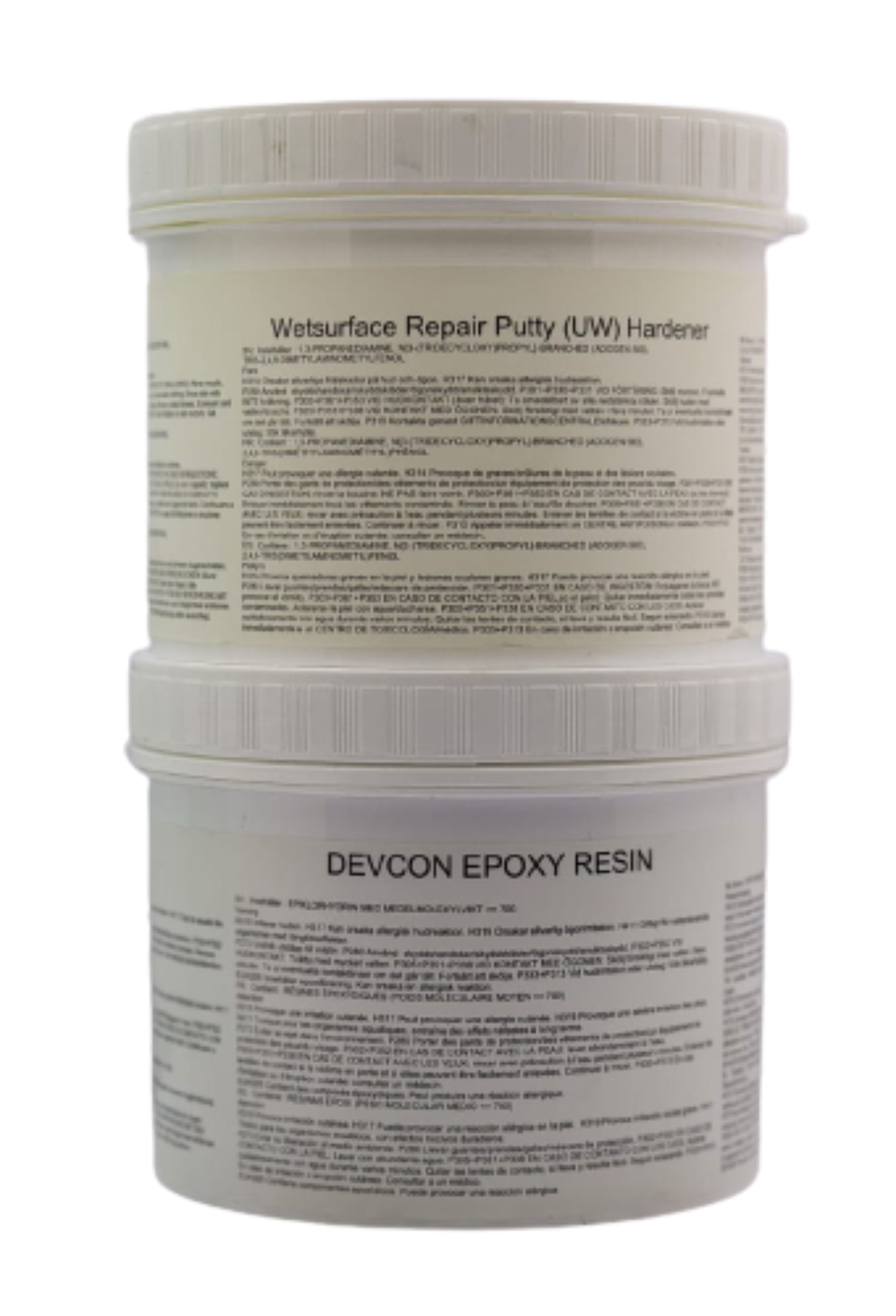

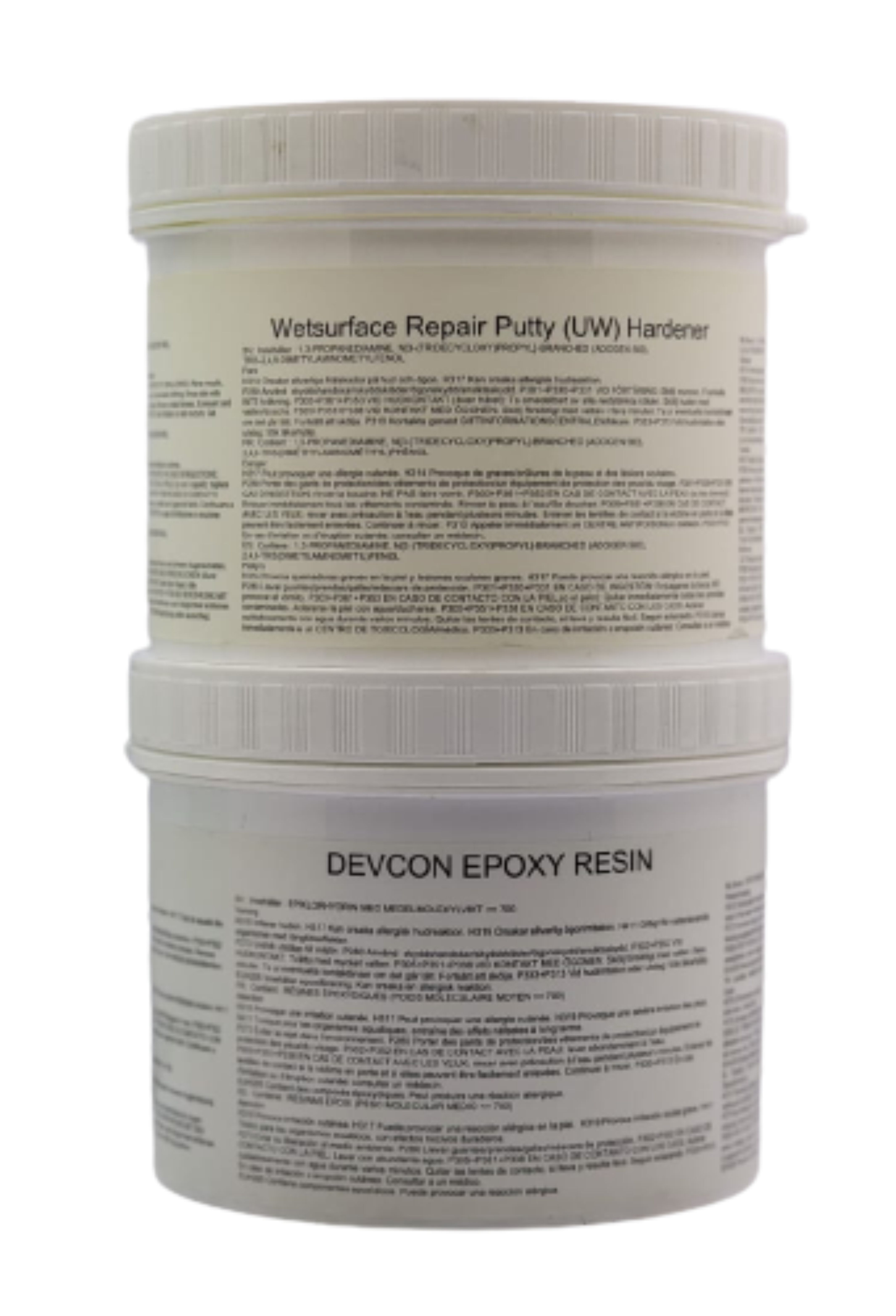

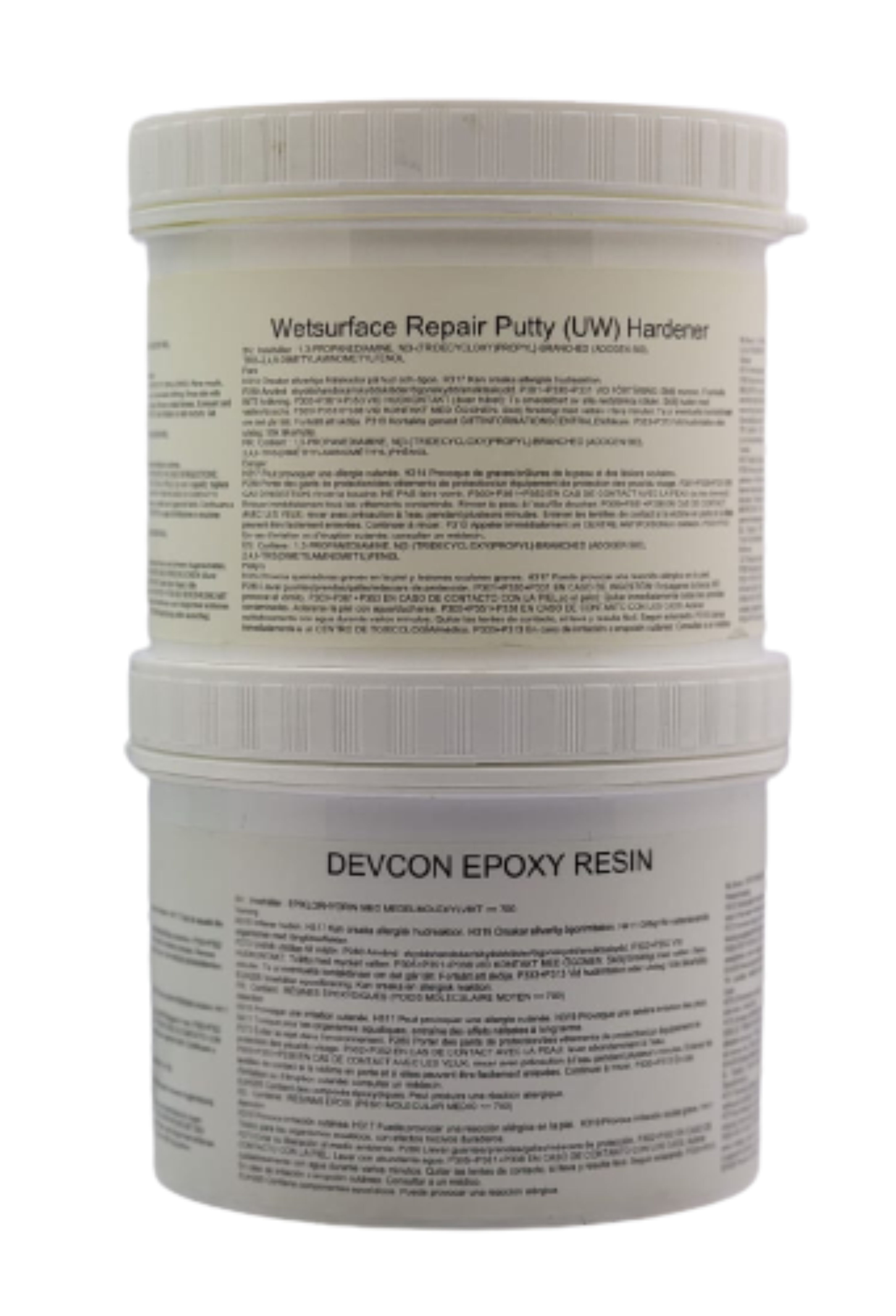

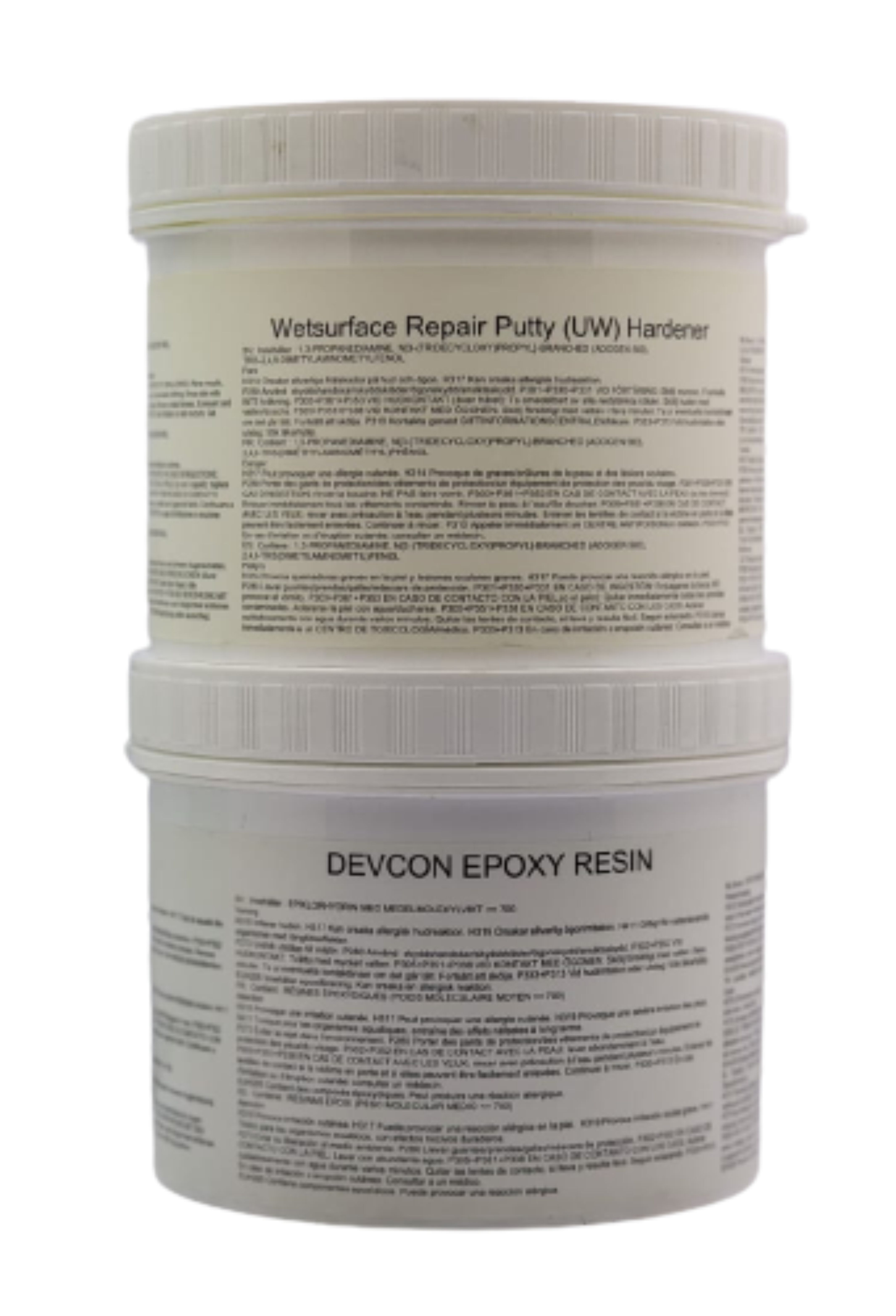

Devcon Wet Surface Repair Putty ( UW )

9000 INR/Piece

Product Details:

- Storage Temperature 200 Fahrenheit (oF)

- Purity 97%

- Application For Sealing, Protecting and Repairing Surface

- Color Grey

- Physical State Liquid

- Click to View more

X

Devcon Wet Surface Repair Putty ( UW ) Price And Quantity

- 9000 INR/Piece

- 1 Piece

Devcon Wet Surface Repair Putty ( UW ) Product Specifications

- 200 Fahrenheit (oF)

- 97%

- Grey

- For Sealing, Protecting and Repairing Surface

- Liquid

Devcon Wet Surface Repair Putty ( UW ) Trade Information

- Surat

- Cheque, Cash Against Delivery (CAD), Cash Advance (CA), Cash in Advance (CID)

- 10 Piece Per Day

- 1 Days

- If order is confirmed we will reimburse the sample cost

- Western Europe, Central America, Australia, North America, Middle East, Eastern Europe, South America, Asia, Africa

- All India

Product Description

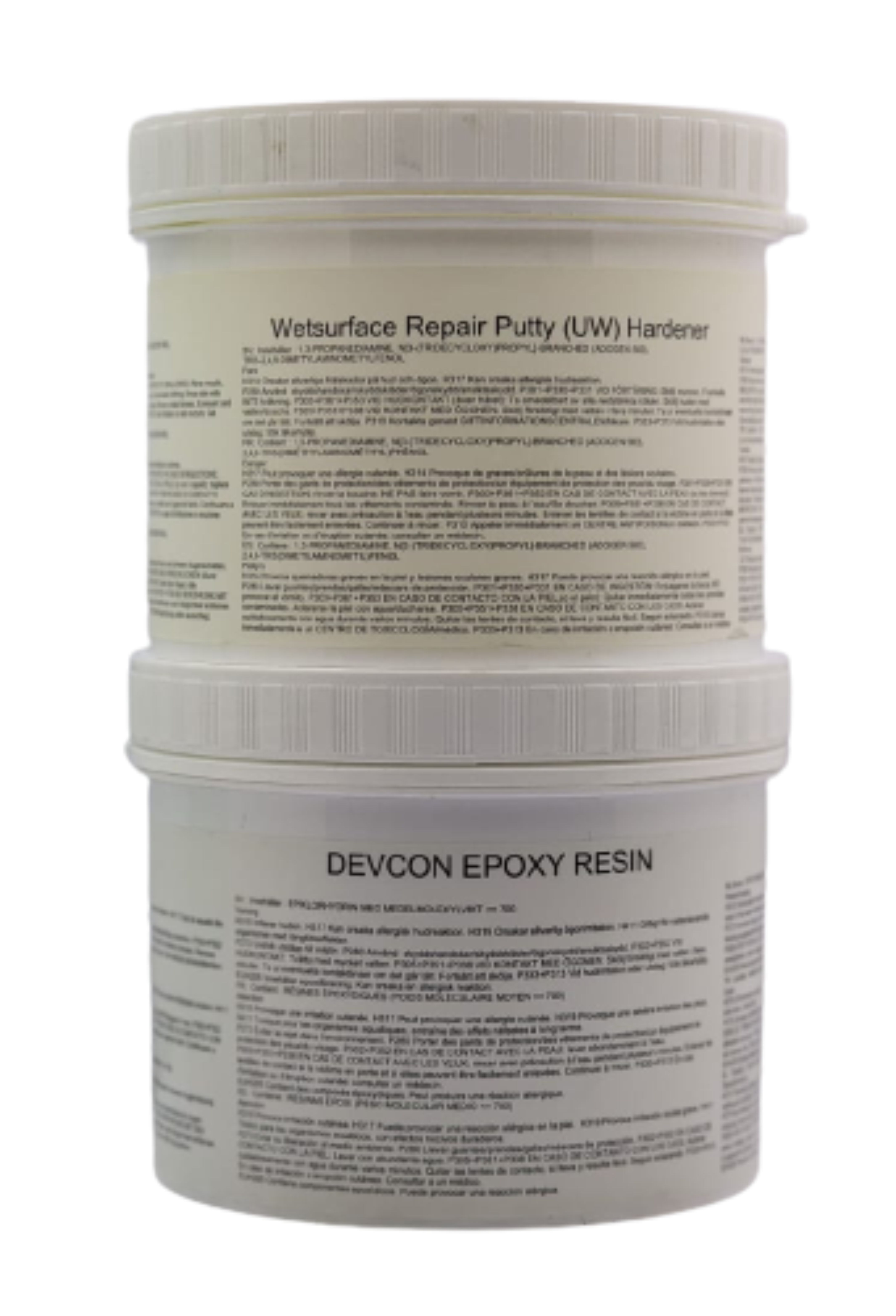

Devcon Wet Surface Repair Putty ( UW )/Under Water Repair Putty Description Makes (effective) repairs to metal, concrete, wood surfaces in wet and dry environments. Intended Use Repairing and refitting pipes, valves, pumps, and tanks. Repair concrete vessels and piping in wet environments. This product will bond to a wet or damp surface. Product Bonds to aluminum, concrete and many other metalsBonds to ferrous and non-ferrous metalsNon-rusting Typical Technical data should be considered representative or typical only and should not be used for specification purposes. Physical Cured 7 days @ 75 F Properties : Color Grey TESTS CONDUCTED Mix Ratio by Volume 1: 1 Cure Shrinkage ASTM D 2566 Mix Ratio by Weight 1.4: 1 Adhesive Tensile Shear ASTM D 1002 Cured Hardness 82 Shore D Modulus of Elasticity ASTM D 638 Dielectric Strength 150 volts/mils Dielectric Constant 8.6 Adhesive Tensile Shear 2,685 psi Compressive Strength 5,625 psi Modulus of Elasticity 7.5 psi x 10(5) in. Flexural Strength 4,990 psi Coefficient of Thermal Expansion 18 [(in.) x (in). x F)] x 10(3) Cure Time 24 hrs Recoat Time 10-12 min. Mixed Viscosity Putty Surface 1. Thoroughly clean the surface with Devcon Cleaner Blend 300 to remove all oil, grease, and dirt. Preparation : 2. Grit blast surface area with 8 - 40 mesh grit, or grind with a coarse wheel or abrasive disc pad, to create increased surface area for better adhesion (Caution: An abrasive disc pad can only be used provide white mesh is revealed). Desired profile is 3 -5mil, including defined edges (do not "feather epoxy). WORKING CONDITIONS: Ideal application temperature is 55o F to 90o F. In cold working conditions, heat repair area to 100 -110o F immediately prior to applying to dry off any moisture, contamination, or solvents, as well as to assist epoxy in achieving maximum adhesion properties. Mixing It is strongly recommended that full units be mixed, as ratios are pre-measured. Instructions : 1. Add hardener to resin 2. Mix thoroughly with screwdriver or similar tool (continuously scrap material away from sides and bottom of container) until a uniform, streak free consistency is obtained. INTERMEDIATE SIZES (1,2,3 lb. units): Place resin and hardener on a flat, disposable surface such as cardboard, plywood, or plastic sheet), Use a trowel or wide- blade tool to mix the material as in Step 2 above. Application Instructions: Spread mixed on repair area and work firmly into substrate to ensure maximum surface contact. Plastic Steel Putty (A) fully cures in 16 hours, at which time it can be machined, drilled, or painted. FOR MAXIMUM PHYSICAL PROPERTIES Cure at room temperature for 2.5 hours, then heat cure for 4 hours @ 200oF. FOR + 70oF APPLICATIONS Storage: Store at room temperature. Compliances: Non e Chemical Resistance : Chemical resistance is calculated with a 7 day, room temp. cure ( 30 days immersion 75oF)FAQs of Devcon Wet Surface Repair Putty ( UW ):

Q: What is the primary application of Devcon Wet Surface Repair Putty (UW)?

A: Devcon Wet Surface Repair Putty (UW) is used for sealing, protecting, and repairing surfaces.Q: What is the physical state of Devcon Wet Surface Repair Putty (UW)?

A: The physical state of the product is liquid.Q: What is the storage temperature requirement for Devcon Wet Surface Repair Putty (UW)?

A: The storage temperature requirement is 200F.Q: What is the purity level of Devcon Wet Surface Repair Putty (UW)?

A: The product has a purity level of 97%.Q: What is the color of Devcon Wet Surface Repair Putty (UW)?

A: The color of the product is grey.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Devcon Epoxy Putties' category

|

JAY AGENCIEZ

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |